FACTORY AUTOMATION

We offer software solutions that are customized for factory applications and designed to enhance the efficiency of manufacturing systems.

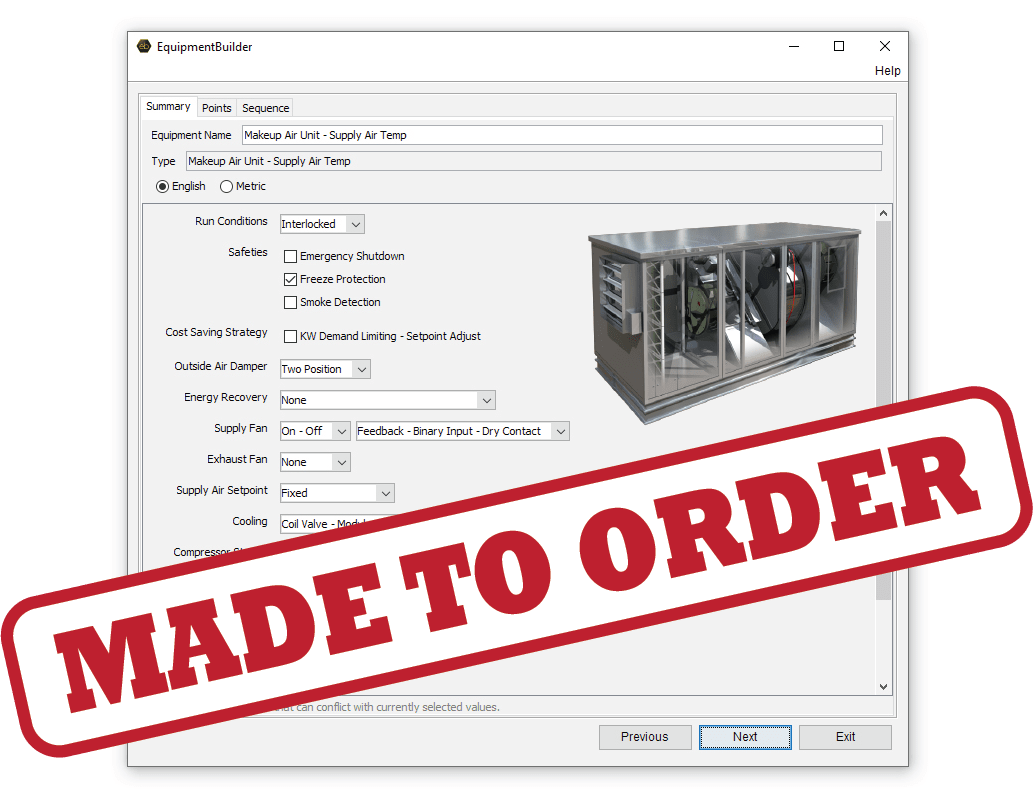

Factory Download Tool (FDT) integrates with your ordering system to capture the unit configuration that is chosen during the ordering process. No more handoffs between sales and engineering means fewer mistakes.

- Capture order details from database source

- Use script to parse for relevant data

- Flexible enough to handle a variety of order formats

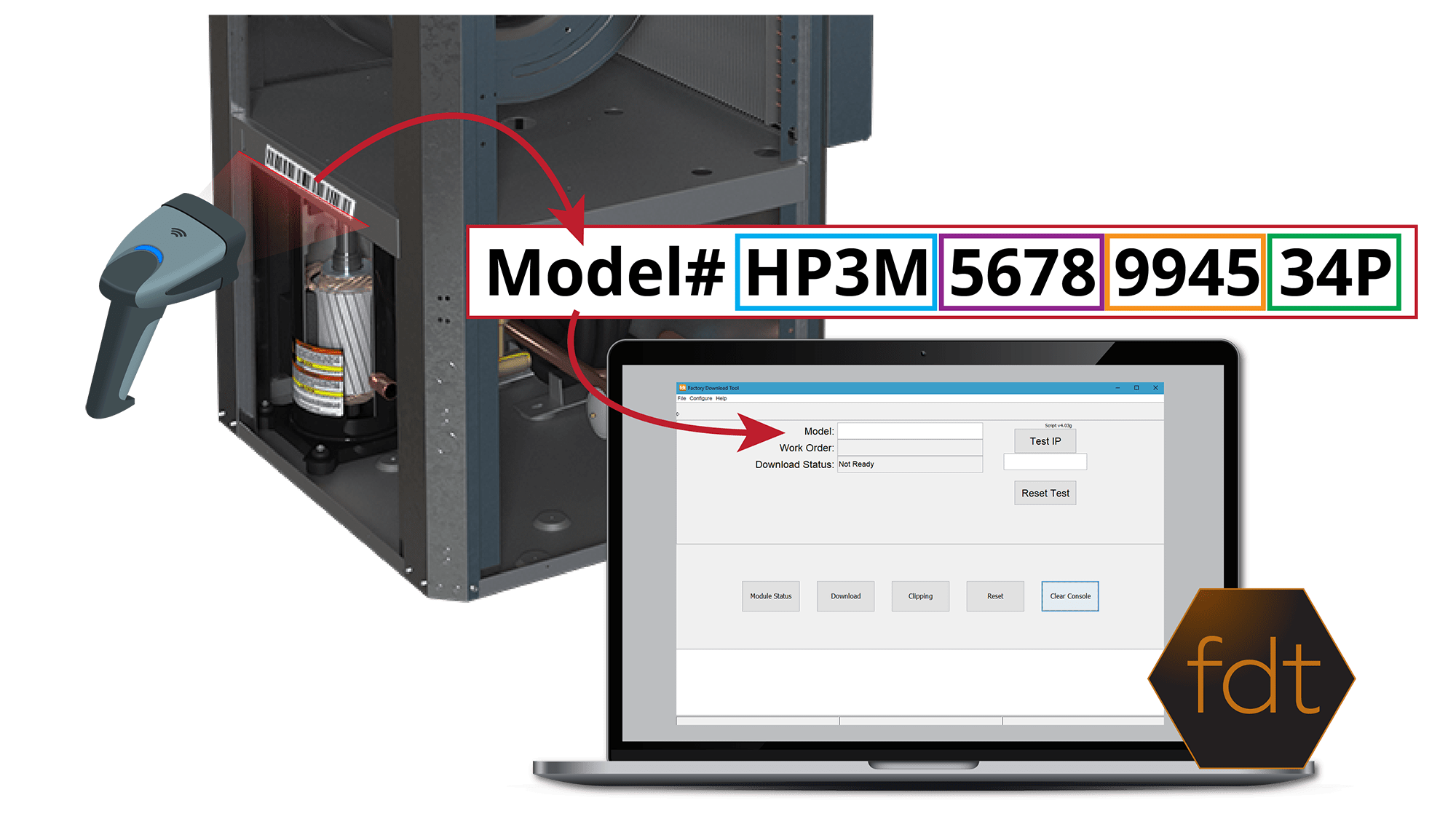

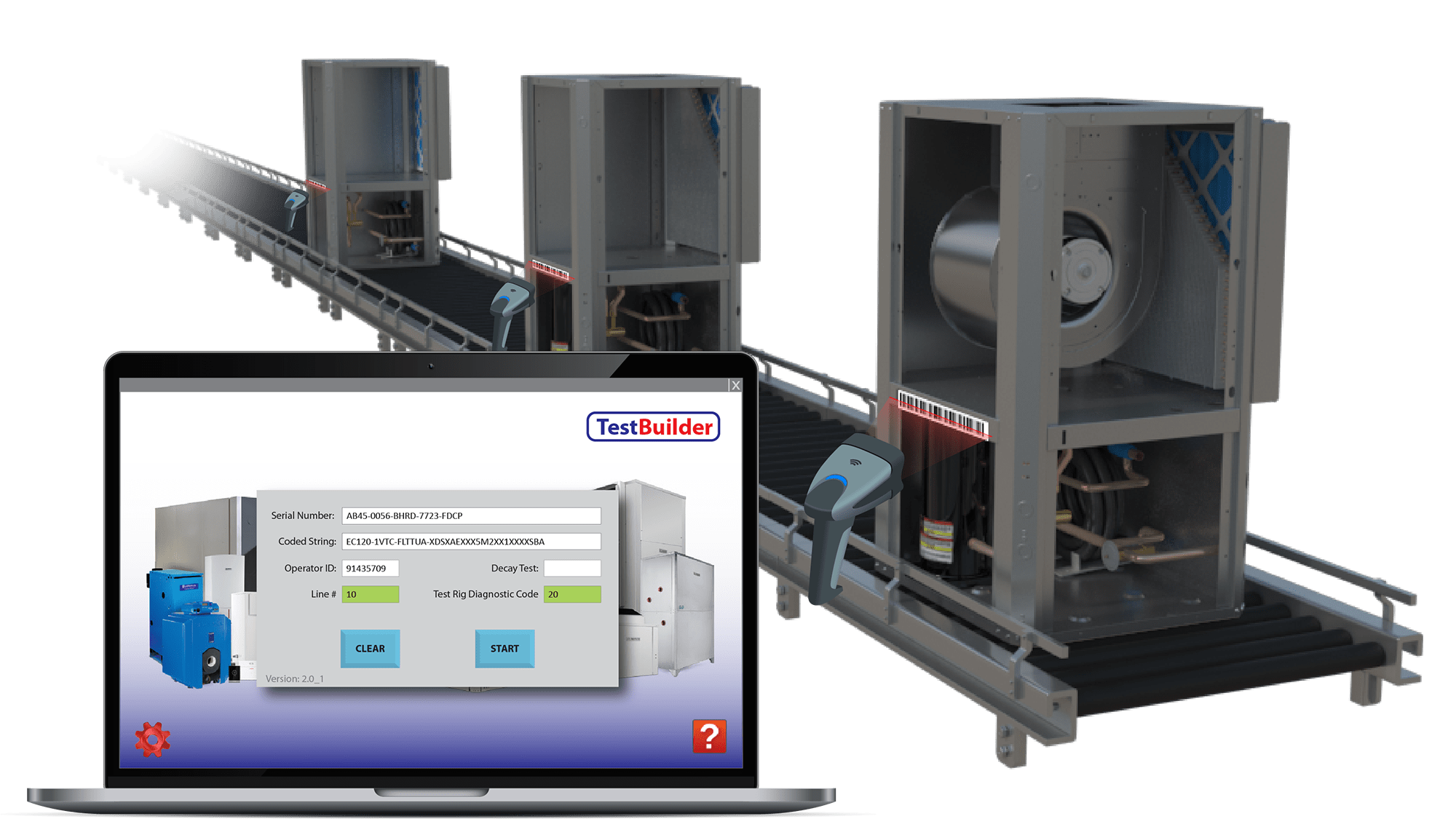

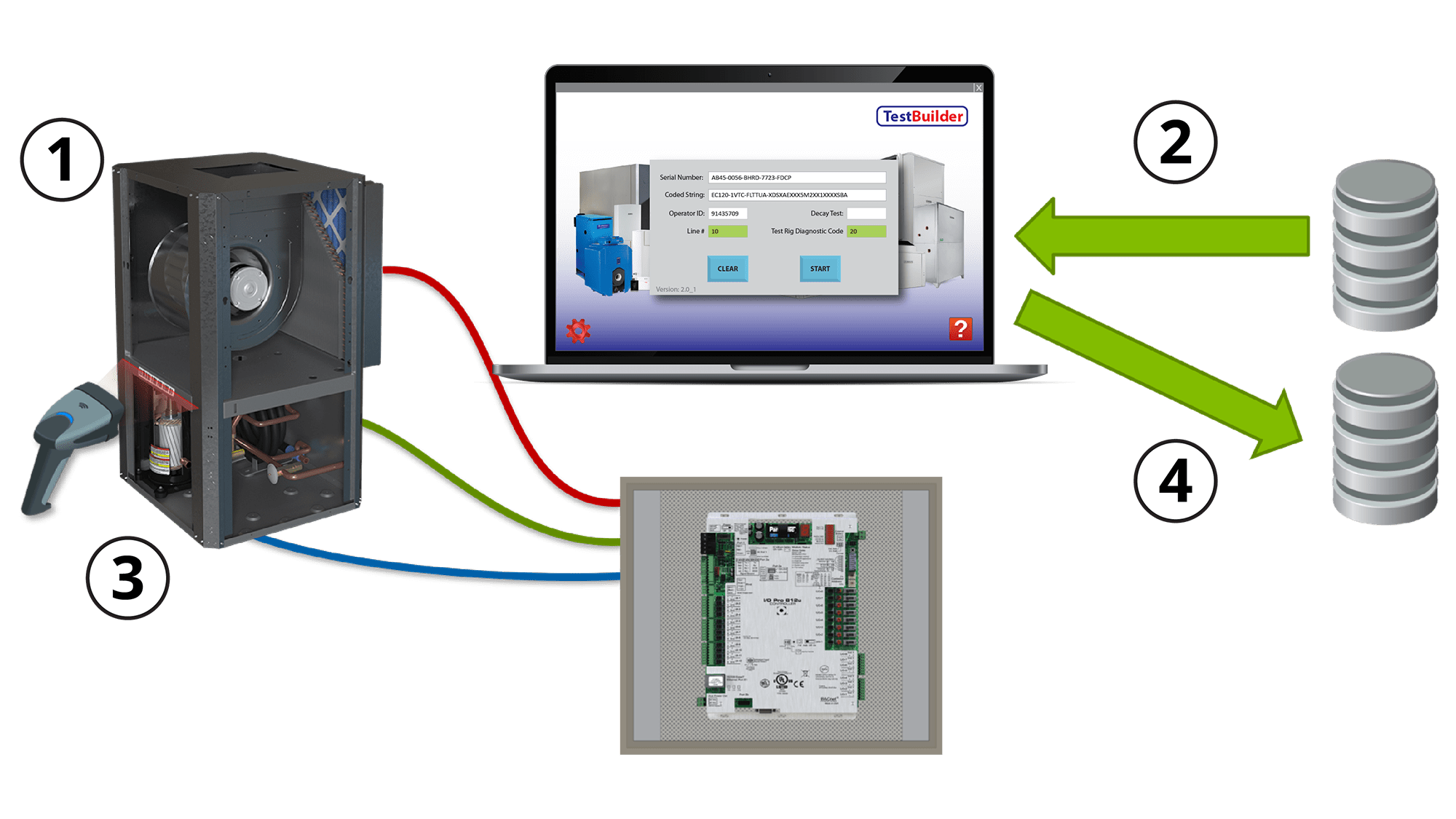

Factory Download Tool (FDT) on the factory floor along with an input device like a barcode scanner can be a tremendous time saver and can significantly reduce errors.

- Provide a customized interface for factory personnel

- Parse model/serial number for key information

- Write controller parameters to database

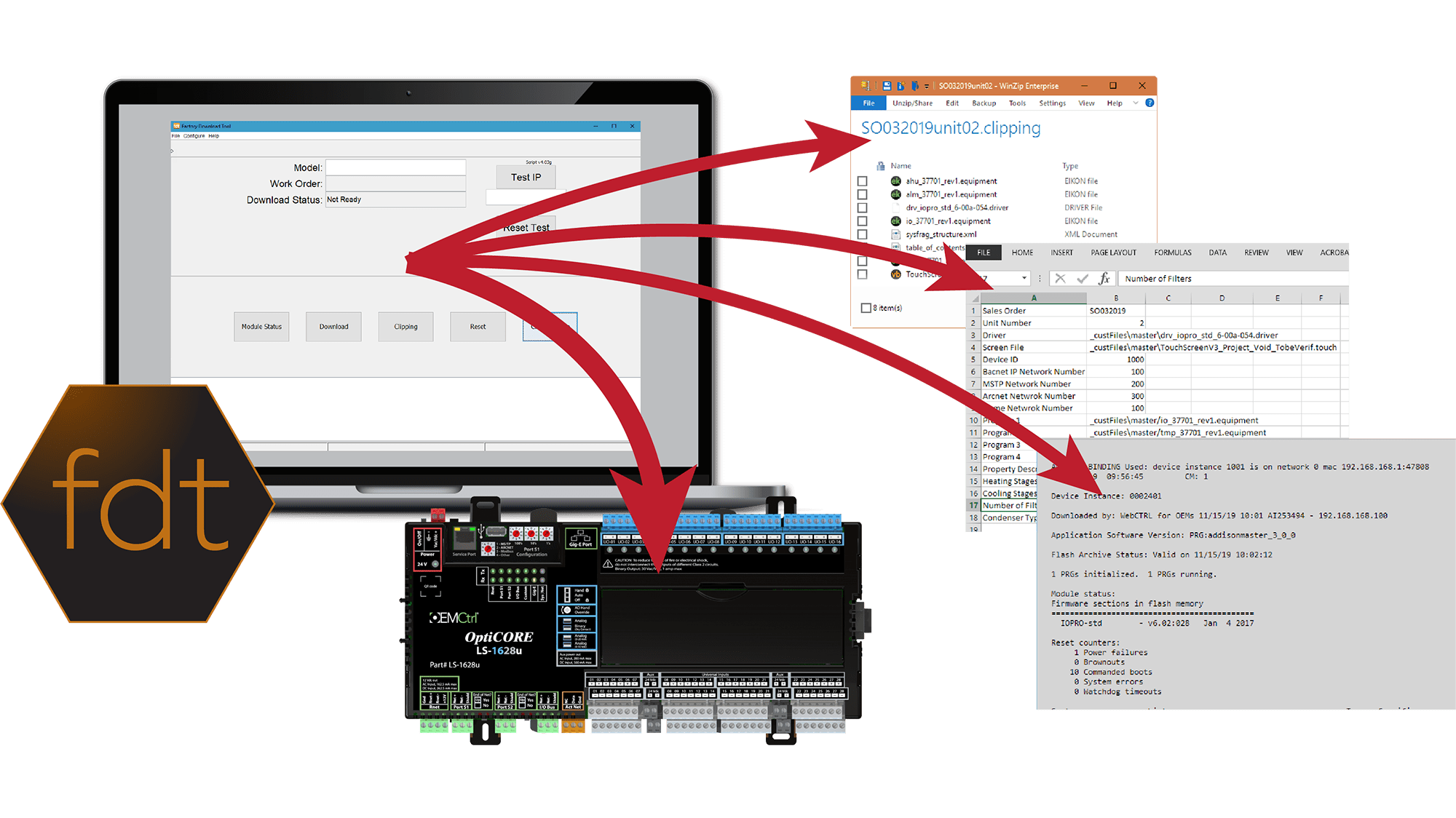

Download controller with custom configuration and create a record of that unique configuration and write it to the right place on the network.

- Generates a clipping file (copy of custom settings)

- Custom points list for integration

- Log file

- Error validation to ensure error-free process

With TestBuilder, testing can be done at the end of the line or it can be done at intermediate stages reducing the complexity of the test and the potential rework required if there is an issue.

- Each test station can be set up to run a different test

- Customizible interface walks the user through the process

- Fix problems early in the process

The panel will consist of a controller to support I/O needs of the station. Sensors measuring temperature, current, airflow switches, etc. are connected to the controller to allow testing of unit components.

- Unit stopped at test station. Model number barcodes scanned

- Model options retrieved from system DB. Test configured from options

- External sensors and relays connected to unit, as instructed by TB

- Sensor values and test results are written to external database