ENGINEERS & SERVICE TECHNICIANS

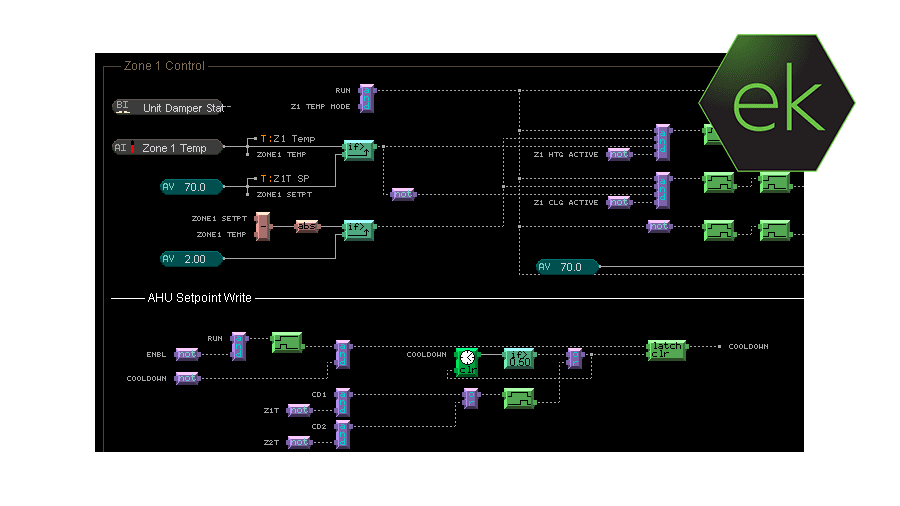

Our software uses graphics and universally understood symbols to make the creation of control logic easy - minimizing engineering time and giving technicians of all skill levels the ability to take advantage of the latest HVAC technology.

If controls are the heartbeat of the equipment, Controls Engineers are the life blood of the control system. These individuals make all the pieces work in harmony and ensure the full potential of the equipment is reached. Success for a controls engineer means:

- Making sure there are not service issues in the field because of control sequence issues

- Meeting the production schedule while satisfying the varying demands of customers who want customization

- Employing control schemes that allow the equipment to be sold with features that are innovative and competitive

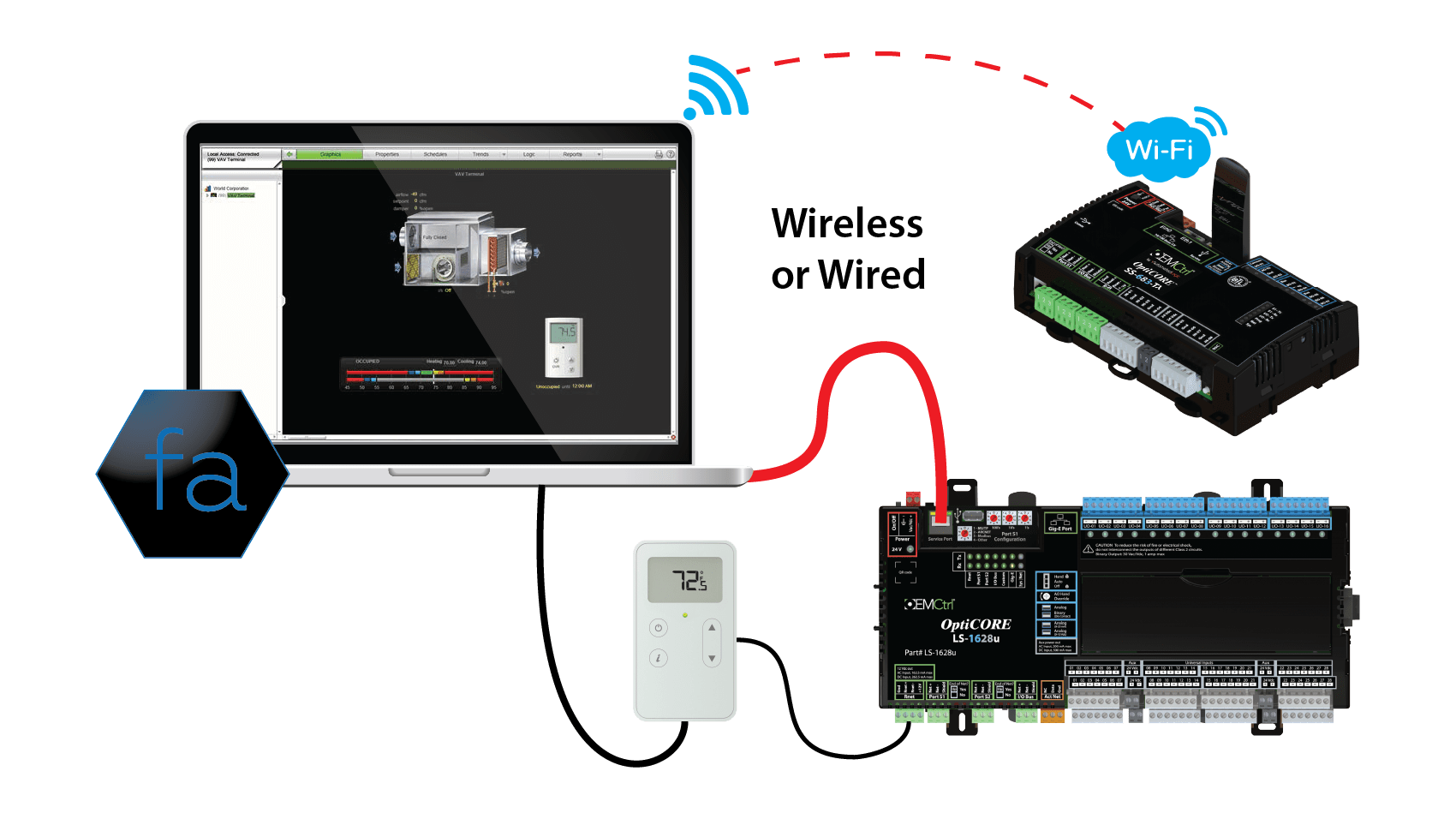

Service technicians operate on the front lines and must have a wide range of knowledge to help with everything from equipment and controls start-up to diagnosing and solving problems under significant pressure and in often uncomfortable circumstances. Success for a service technician means:

- Having the right tools to get the job done

- Being able to do what needs to be done quickly and without having to waste time sitting around

- Working with tools that are intuitive and easy to learn

- Being empowered to fully diagnose and fix problems themselves

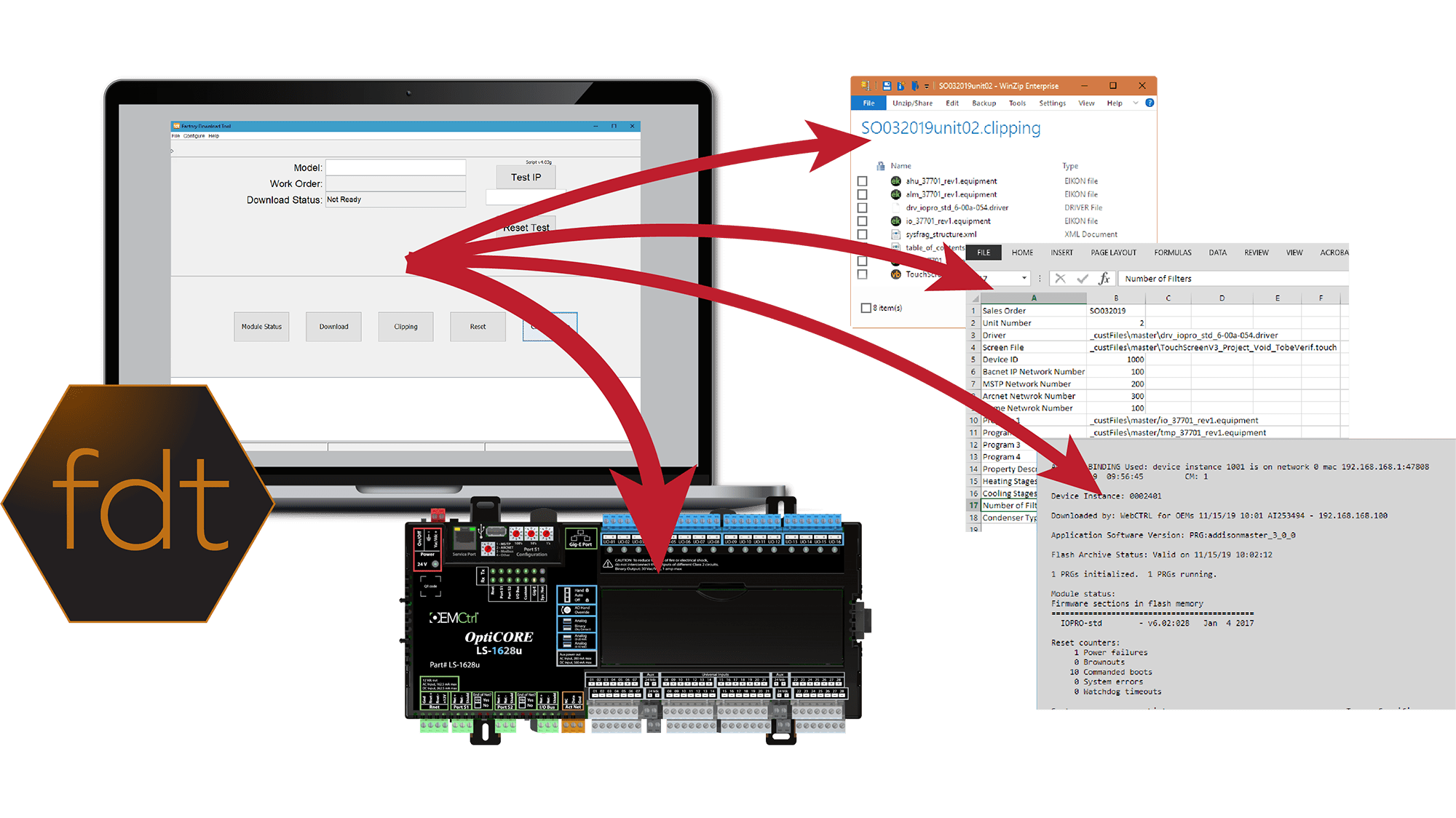

Manufacturing engineering hasn’t traditionally been a part of the story of HVAC controls, but as factory-mounted controls have increased in frequency, companies have been challenged to find ways to improve process flow and product quality from the orders all the way through to shipping. Success for a manufacturing engineer means:

- Improved TAKT time by a significant amount by implementing FDT into the process

- Significant reduction in setup and configuration errors as a result of automation

- Increased configuration capabilities as a result of automating